Best Welding Nozzles for Heat Guns – Precision & Performance

Upgrade your vinyl heat gun with high-quality welding nozzles designed for sheet vinyl, resilient flooring, and commercial vinyl installations. Our selection includes brass nozzles, copper nozzles, and nickel-plated nozzles, ensuring high heat resistance, optimized gas coverage, and long-lasting durability.Whether you’re a flooring installer or working on specialized heat welding applications, choosing the right nozzle is critical for achieving a perfect seam, strong bond, and precise welding joint.

Why Choose Our High-Quality Welding Nozzles?

- Optimized for Vinyl Heat Guns – Ensures proper temperature setting for heat welding flooring materials like PVC, linoleum, and rubber.

- Heavy-Duty Nozzles for High Temperatures – Made from copper, brass, and nickel-plated metal for superior durability.

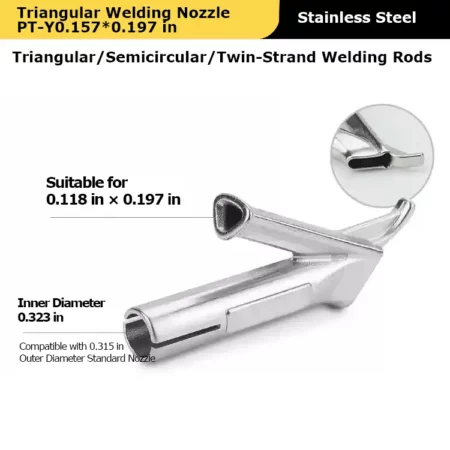

- Wide Range of Nozzle Styles – Choose from angled, flat, rectangular, and round nozzles for different welding processes.

- Anti-Spatter & Long Nozzle Life – Designed to reduce molten metal spatter and extend nozzle life.

- Compatible with Multiple Flooring Materials – Ideal for commercial vinyl flooring, sheet vinyl, and resilient flooring applications.

Types of Welding Nozzles for Vinyl Heat Guns

🔹 120° Flat Nozzle – Designed for smooth and even heat distribution during heat welding.

🔹 90° Angled Tube Nozzle – Perfect for tight joint access, directing high heat precisely.

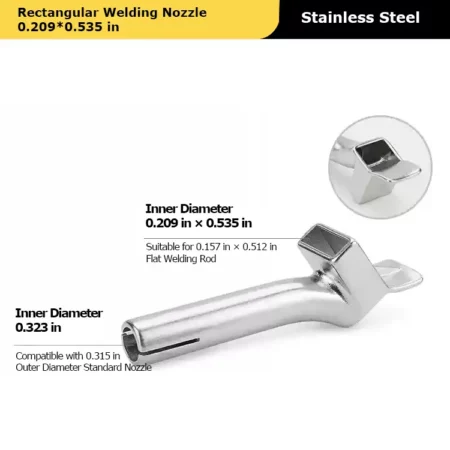

🔹 Rectangular Nozzle – Covers a larger bore size for uniform heating of flooring materials.

🔹 Round Adapter Nozzle – Provides optimized gas coverage for focused heat application.

🔹 Hook-Shaped Welding Nozzle – Allows for controlled heat flow, improving the weld pool and ensuring a strong bond created between materials.

🔹 Slip-On Nozzles & Thread-On Varieties – Available in different inner diameters for precise gas pressure control.

🔹 Nickel-Plated Nozzles & Copper Nozzles – Withstand high temperatures and prolong nozzle life.

🔹 Thicker Insulators & Heavy-Duty Nozzles – Help maintain consistent heat for optimal welding processes.

How to Choose the Right Welding Nozzle?

1️⃣ Consider the Material & Shape – Brass nozzles, copper nozzles, and nickel-plated nozzles offer different heat resistance and durability levels.

2️⃣ Optimize Gas Coverage – The right nozzle helps maintain stable shielding gas flow, preventing spatter and ensuring clean welding joints.

3️⃣ Check Inner Diameter & Bore Size – Affects weld puddle control, gas pressure, and heat distribution.

4️⃣ Ensure Proper Storage – Keep in a small plastic bag within its original packaging to protect from contaminants.

Best Practices for Nozzle Maintenance & Longer Arc-On Time

✔ Use Anti-Spatter Compound – Prevents buildup and extends nozzle life.

✔ Store Properly in a Small Plastic Bag – Protects against debris and damage.

✔ Replace Nozzles with Worn Inner Diameter – Ensures gas pressure remains stable for correct welding methods.

✔ Inspect for Heat Distortion & Pressure Issues – Maintaining the largest bore size prevents gas restriction.

View Catalog & Request Your Quote

- Free samples (conditions apply).

- Direct factory pricing with volume discounts.

- Private labeling and packaging on request.

Frequently Asked Questions– Welding Nozzle

1. What types of welding nozzles are available for vinyl heat guns?

Our selection includes flat nozzles, angled nozzles, round nozzles, hook-shaped nozzles, and rectangular nozzles, each designed for different heat welding applications. Flat nozzles provide even heat distribution, while angled nozzles offer better joint access for precise welding.

2. How do I choose the right welding nozzle for vinyl flooring installation?

Consider these factors:

Flooring material (PVC, linoleum, or rubber)

Seam width & depth (narrow seams require precise nozzles)

Heat distribution needs (flat nozzles for even coverage, round nozzles for concentrated heat)

Joint access (angled nozzles help in tight spaces)

3. How can I extend the lifespan of my welding nozzle?

Follow these maintenance tips:

Use an anti-spatter compound to prevent molten material buildup.

Proper storage – Keep the nozzle in a small plastic bag to prevent contamination.

Regular cleaning – Remove residue after each use to maintain consistent heat distribution.

Avoid excessive pressure – Applying too much force can deform the nozzle.

4. What is the recommended temperature setting when using welding nozzles?

The temperature setting depends on the flooring material:

PVC & commercial vinyl: 350-450°C (662-842°F)

Linoleum: 200-300°C (392-572°F)

Rubber flooring: Adjust based on thickness and adhesive properties

Always start at a lower temperature and gradually increase to avoid burning the material.

5. Can I use the same welding nozzle for different flooring materials?

Yes, but different materials may require different heat settings and nozzle designs. For example:

Thin sheet vinyl works best with a flat or round nozzle.

Thicker resilient flooring may need a hook-shaped nozzle for precise heat application.

Narrow seams require nozzles with a smaller bore size for better control.